Air Quality Management in Mining Areas

To minimize dust generation during mining processes, modern technologies are adopted and regularly monitored – surface miners, fog canons, mist sprayer, wheel washing, mechanised road sweeper, CAAQMS, wet drilling to minimize dust generation. Drill machines are also fitted with dust suppression system. More and more use of surface miners/BWEs minimizes the requirement of drilling and blasting and thus the pollution load. Periodical maintenance of vehicles is carried out as per Manufacturer’s standards to minimize the emissions.

Dust suppression systems are installed at loading, transfer and unloading points in mines. Additionally, water-spraying systems for arresting fugitive dust in washeries, CHPs, Feeder Breakers, Crushers, belt conveyors, haul roads and coal stock areas are installed.

All roads connecting mines, CHP’s, workshops and colonies have been black topped to prevent dust from becoming airborne.Mist spray systems have been introduced and the trucks are being covered by tarpaulin. Fog canon, wheel washing system, mechanical road sweepers etc. are being deployed for control of air pollution.During FY 2021-22 to FY 2023-24, Coal/Lignite PSUs have deployed/installed 431 mist sprayer/fog canon, 19 wheel washing, 26 mechanical road sweeper and 93 CAAQMS.

Coal companies are commissioning First Mile Connectivity (FMC) Projects aimed to replace the system of convention loading & road transport with rapid mechanized loading system with transport through Rail/MGR/Conveyors/tube conveyor network. Some of the projects have already been completed and others are in pipeline. These projects are not only minimizing air pollution but also results in substantial reduction in carbon footprint.

Dust generation from the OB dump due to wind is controlled significantly by planting grasses on slopes and plants on dump top soon after their formation. Avenue plantation is raised along roads for dust control. Plantation is done around the quarry and OB dumps, which serves as a barrier to prevent the dispersion of air borne dust. Wind screens have been created to restrict the movement of dust within a limited area.

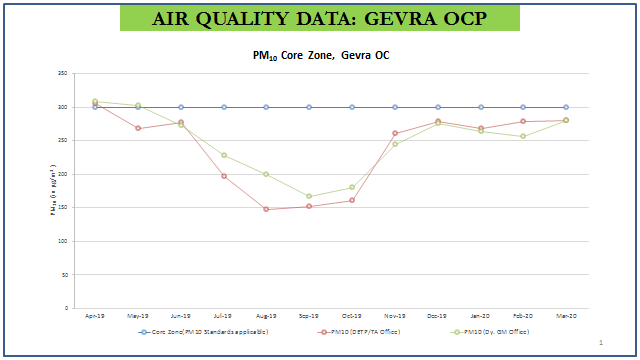

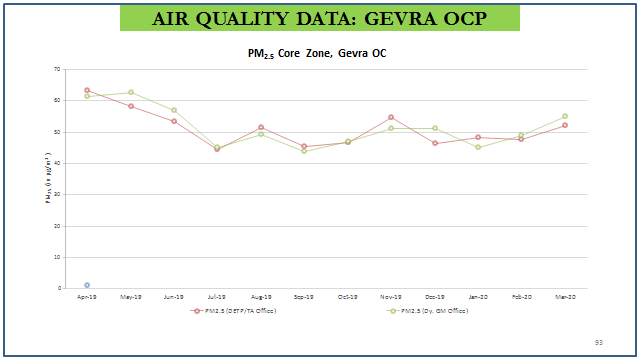

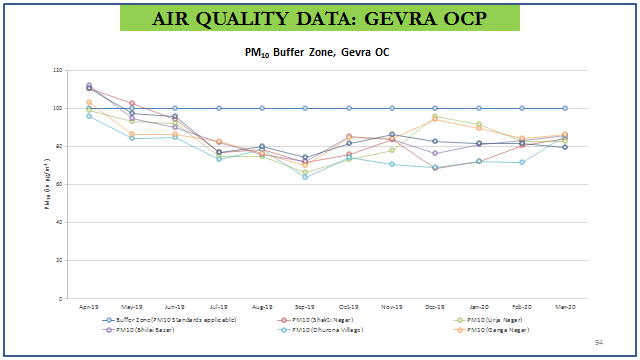

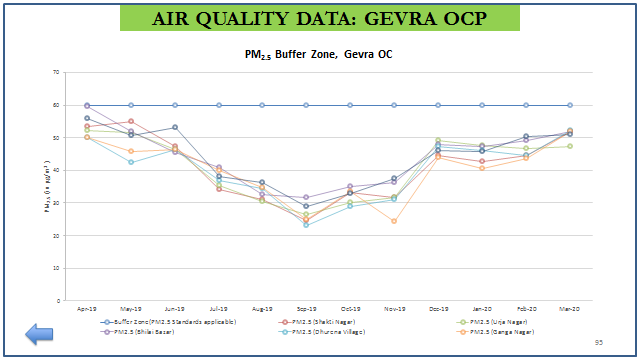

The ambient air quality in and around coal mines is routinely monitored as per statutory stipulations and their results are shared with regulatory agencies. Continuous Ambient Air Quality Monitoring Systems (CAAQMS) have also been installed in opencast mines which are connected to SPCB websites for real time monitoring of Ambient Air Quality Parameters. Additional pollution control measures are undertaken, if required, to bring the air quality level within permissible limits.

With various emission control and mitigative measures in place, the standards of ambient air quality in and around mining areas are maintained within the prescribed limits.

कोयला मंत्रालय

कोयला मंत्रालय